The Impact of Pharma Packaging Machines on Product Quality

In the highly regulated pharmaceutical industry, ensuring quality is paramount and this includes the packaging. Pharma packaging machines can today meet these stringent standards seamlessly, and also bring a wider range of benefits to the sector.

As a leading packaging machine manufacturer, we understand the pivotal role of automation in enhancing and maintaining consistent product quality. In this article, we’ll delve into the impact that pharma packaging machines have, not only on quality, but also on the bigger operational picture.

The benefits of automation for the pharma industry

Advancements in packaging machinery have been largely driven by demand, placing pressure on traditional production lines and packaging processes. While challenging for manufacturers, rising demand also spells opportunity and this in turn is creating a circle of innovation within the industry.

Compliance is tough and understandably stringent in the sector, and regulations are consistently updated to keep up with global changes. This is a contributory factor for many manufacturers, who are turning increasingly to automation for the answers to these hard-to-predict challenges.

Product integrity and shelf life

Pharma and hygienic products need both packaging and processes to protect from a range of environmental elements, such as moisture, oxygen and light in some situations. Advanced automated packaging lines are tailored to meet these requirements, creating a clean environment and utilising advanced materials designed to maintain product integrity and keep medications effective throughout their shelf life.

Precision packaging and consistency

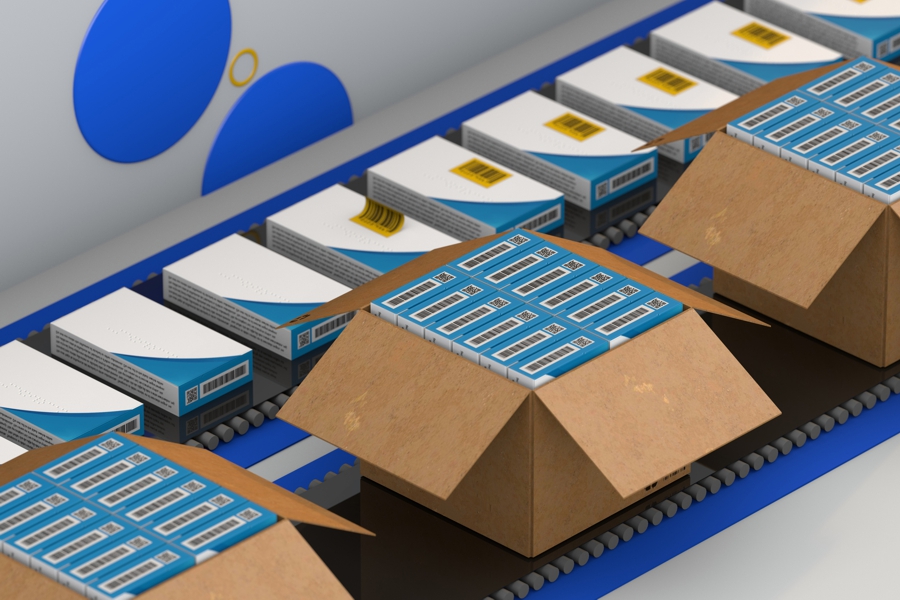

Creating consistency is a crucial part of pharma or any hygienic product packaging, and one that is difficult to maintain with a manual line. Automating key stages with modern machinery ensures that each package meets precise specifications, reducing variability and minimising the risk of defects or packaging contamination.

Traceability, safety and compliance

Regulatory demands for traceability are increasing all over the world, now becoming a vital part of pharmaceutical packaging requirements. Some of the latest automated pharma packaging machines are able to integrate serialisation and improve labelling as a result.

To address rising hygienic packaging standards, machines introduce a clean environment that cannot be achieved as easily without automation. This brings the opportunity to minimise human interaction and vastly improve quality control and safety standards too.

Speed, output and cost efficiency

Automation in key areas of the packaging line not only improves quality and consistency. It can contribute significantly to cost efficiency, increasing speed, output and overall distribution. Some of our packaging machines can switch between different packaging formats and sizes quickly, with no parts changes. This minimises downtime and enhances the scalability and flexibility of the entire line as a result, allowing businesses to be more responsive to market demands.

How to introduce automated pharma packaging machines

The evolution of pharma packaging machines has resulted in a profound impact on product quality and hygienic standards, while simultaneously improving operational processes. Find out how pharma packaging automation helped a US supplier find a solution in our case study here.

Whether you are considering introducing automation onto an existing production line or creating a new, clean packaging environment, we’re here to help. We build a range of machines to pack pharma products and can tailor to unique requirements through close consultation. We have worked with pharmaceutical products producers all over the world, helping to streamline through full or partial automation. Contact us today.