Packaging Machines for a Dynamic Market

Today, in the rapidly evolving landscape of consumer demand, the packaging industry faces a dual challenge. Meeting consumer preferences and the adoption of sustainable practices as environmental concerns grow.

As leading packaging machines manufacturers, we understand that machinery must also evolve – to become more flexible, efficient, scalable and adaptable to the dynamics of market conditions. In this article, we’ll explore how, if done correctly, implementing packaging machinery can give you the tools you need to drive growth.

Adapting to consumer preferences

Consumer preference is influenced by a wide range of factors and is a continual state of change. Things like convenience, the environment, widening choice, accessibility and even consumer advertising are driving forces behind preference.

The response from the packaging machinery sector is the development of a more flexible approach. Machines that can adapt quickly to a wider range of packaging materials and formats, for instance, give their operators much greater scope to handle growth. If machines can switch between formats with minimal downtime, manufacturers gain the ability to cater to different consumer segments and quickly introduce new product lines.

Embracing automated packaging machines

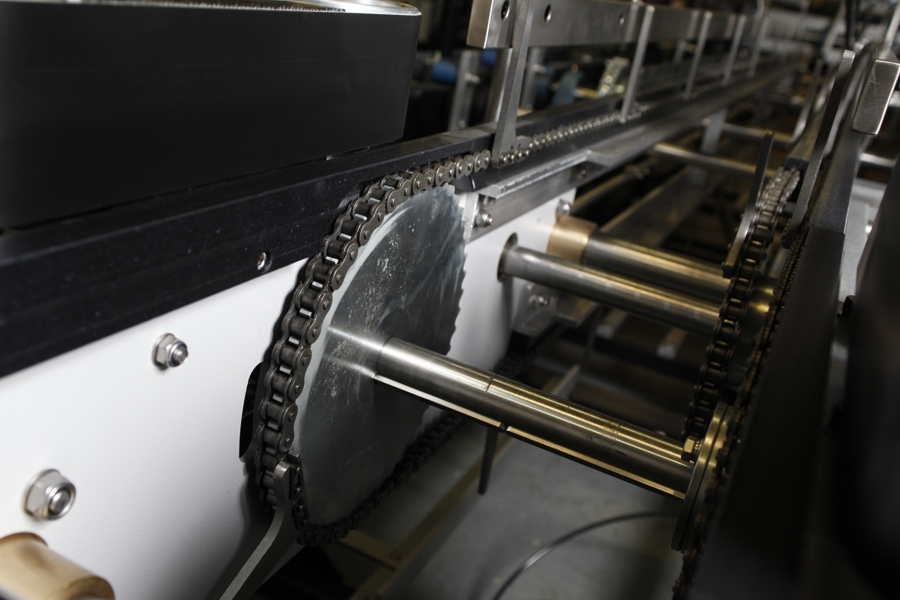

The uptake in the adoption of automated packaging machines has been largely driven by the need for increased speed and efficiency in operations. Machinery can today perform the most complex tasks – carton erection, filling, sealing and collation for end-of-line distribution – with minimal human intervention. This means enhanced precision, consistency and quality control, in addition to the vital increase in speed and distribution.

With automation comes not only efficiency, but also a dramatic reduction of the reliance on manual and energy resources. Simplified maintenance, quality control and real-time performance monitoring are all additional benefits that can contribute to the optimisation of operations, regardless of the sector. When combined, embracing automated lines can help manufacturers to maintain high levels of productivity while adapting easily to market changes with vital scalability ‘built-in’.

Sustainability as a driving force

Today, sustainability is fast becoming a fundamental requirement for packaging operations. No longer just a trend, consumers are increasingly expecting sustainable practices, ethics and processes – before they even get to the packaging materials themselves. With expectations growing ever-higher, modern packaging machinery is designed to:

- Minimise energy consumption

- Handle recyclable and biodegradable materials

- Minimise waste

- Maximise efficiency

- Meet compliance

- Be fully scalable

- Optimise resource use

Can we support the evolution of your packaging line?

At the forefront of innovation, packaging machines are adapting successfully to a dynamic, fast changing consumer market. Demands for flexibility, efficiency and sustainability will continue to change and environmental matters will become more pressing. Implementing automated packaging machinery and sustainable practices will become crucial in ensuring a dynamic response and to stay ahead in a competitive market.

At Jacob White packaging, we build machines that can help you not only satisfy consumer demand, but also contribute to a more sustainable operation overall. Talk to us today and let us help.